HISTORY OF DAMASCUS STEEL

Close-up of an Iranian 18th century forged Damascus steel sword

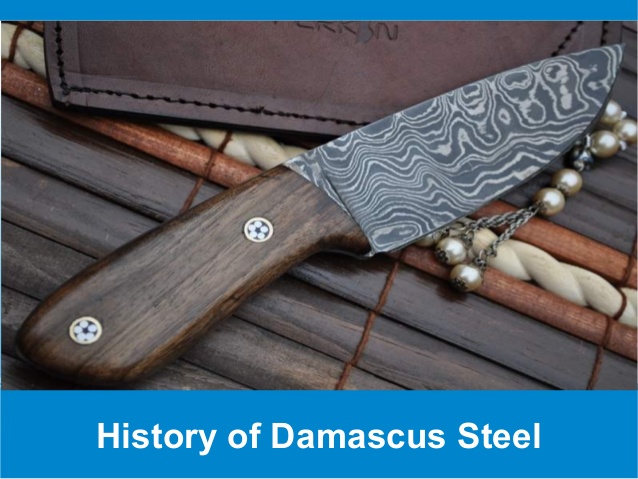

Damascus steel was a type of steel used in Middle Eastern swordmaking. Damascus steel was made from wootz steel, a steel developed in India around 300 BC. These swords are characterized by distinctive patterns of banding and mottling reminiscent of flowing water. Such blades were reputed to be tough, resistant to shattering and able to be honed to a sharp, resilient edge.

The first method of manufacturing Damascus is not popular. Due to the diversity of materials and production techniques, modern metal replacement efforts have failed completely. Despite this, several people in modern times have claimed that they have discovered the ways in which Damascus's South African nation has been formed.

The reputation and history of Damascus have led to many talks, such as the ability to cut a bomb or cut down the hair, but there is no evidence of supporting such claims. The German research team published a report in 2006 revealingnanowires and carbon nanotubes on a construction project from Damascus. This is also included in the National Geographic and New York Times. While some modern-day sophisticated artifacts can succeed in these swords, a chemical reaction in production makes unique metals in their time, such as Handmade Damascus Steel Brass Bolster output and hard work at one time. During the smell process to obtain Wootz metal plants, body and woody biomass are used as carburizing additives and certain rich iron types in microalloying structures. The bees will now be operated and operated in Damascus, and research now indicates that carbon nanotubes can be found on the green hills, indicating how nanotubes are made of iron. Some experts expect to find such nanotubes as numerous as they are closely analyzed.

Comments

Post a Comment